|

|

|

|

|

|

| Evolution of the U.S. Army Ski and Mountain Boot During World War II | |||||||||

Over the course of two years the U.S. Army ski and mountain boot evolved from a cloned civilian ski boot unsuitable for military use to a multipurpose boot that could be used for skiing, climbing, and hiking. The Army created four basic patterns during the war and two of them had two variations. The identification system shown below (Type 1, Type II, etc.) is my own system for conveniently differentiating the patterns. The Army didn't identify the different patterns by type. They just changed the name to reflect the changing role. The names shown below in italics are the official Quartermaster names for that pattern boot. |

|

||||||||

Each boot came from the factory marked with the maker's name, the purchasing depot's name, the boot size, the contract date, and the contract number stamped inside the boot on the fleshy side of the leather. Occasionally, the depot inspector's stamp can be found inside the boot, as well as the specification number. |

|||||||||

Click on the small images for larger versions. |

|||||||||

| Type 1 Boot, Ski  The Army's first ski boot was adopted in May 1941 and was based on Tentative Specification BQD 31. The boot was patterned after the typical pre-war civilian ski boot. |

|

||||||||

| Type 2 Boot, Mountain and Ski  Tentative Specification BQD 31A, May 12 1942, introduced the high box toe typical of WW II Army ski boots. It was based on an army last to accommodate a felt insole and heavy wool socks, but still had a flat leather sole with no toe spring. |

|||||||||

| The large vamp that covers much of the toe box and the six lines of stitching make the BQD 31A boot easy to identify. | |||||||||

| BQD 31A boots had a distinctive three-piece tongue made of leather, foam, and leather. | |||||||||

| Type 3 Boot, Ski-Mountain  Specification BQD 31A boots were not tested before adoption and their many flaws quickly became apparent. An improved design was created and production began in October 1942. This design formed the basis of Tentative Specification BQD 31B published in January 1943. |

|||||||||

| The toe box wings carried back to the heel counters and eliminated the forward facing seam and six lines of stitching of the BQD 31A boots. | |||||||||

| BQD 31B boots had smooth leather soles with toe spring and a leather heel with rubber insert. | |||||||||

| Type 3A Boot, Ski-Mountain, with Nails  Tentative Specification BQD 31B boots were produced in two version for different missions. Half of the boots had a smooth sole (shown above) for skiing and half were mountain boots with steel Tricouni nails added for climbing and marching. |

|||||||||

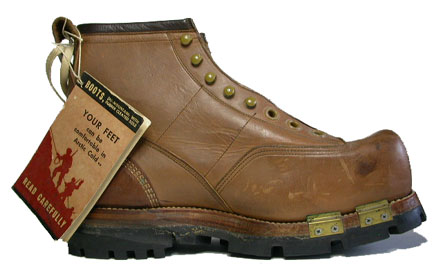

| Type 4 Boot, Ski-Mountain with Rubber Cleated Sole  BQD 31B boots were an improvement, but the need for two versions was impractical. Work began in November 1942 on adapting rubber Bramani soles to the BQD 31B boot and in June 1943 contracts for rubber-soled mountain and ski boots were issued to three companies. |

|||||||||

| Attaching the one-piece, molded rubber sole to the ski boot created a technological challenge that took until mid-summer of 1943 to overcome, but the sole proved to be one of the Quartermaster Corps' major innovations during World War II. The rubber sole gave better over-all traction, was quieter on rocks, and worked well for both marching and skiing. | |||||||||

| Type 4A Boot, Ski-Mountain with Rubber Cleated Sole  In late September 1943 the specification for rubber-soled ski/mountain boots was published as Tentative Spec. BQD 31C. This was the final version ski / mountain boot produced during World War II. |

|||||||||

| Specification BQD 31C called for the maker to emboss the boot's size and a two-letter code near the top of the boot on the outside. The code identified the boot's maker. For example, boots marked "FX" were made by the Freeman Shoe Corporation. | |||||||||